Original Designs

Features of Flow-Through Design

Posted by Quan Ngo on

The FLOW THROUGH design manifold effectively prevents contamination when several samples are injected in a common line of flow. The figure on the left shows a conventional manifold, while the right shows the FLOW THROUGH design. ① The buffer (blue area) flows in the common line from the left side port to the right side port in both of the manifold designs. ② The sample is injected from the front side individual port to the common line, when one of the valves are open. ③ In the conventional design, since the sample remains in the vertical flow path, CONTAMINATION...

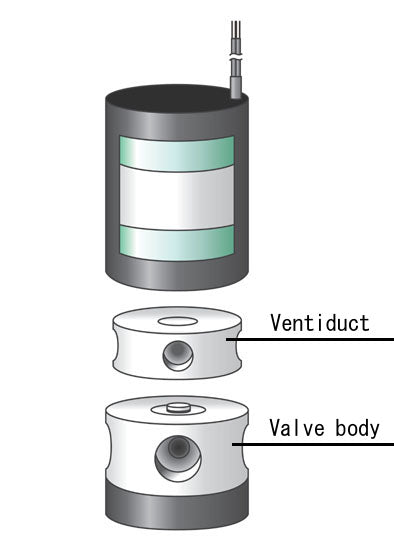

Ventiduct

Posted by Yuki Tokuda on

Takasago's VENTIDUCT is an optional part which is fitted between a valve body and the solenoid. It has ducts for ventilation and heat radiation. It is used as follows. ・With volatile and corrosive fluids ・With fluids which are temperature sensitive ・By users of high temperature fluids EFFECT of VENTIDUCTVentiduct provides the following protection: ・ The "VENTIDUCT" option protects the metal parts of the solenoid from any volatile corrosive gases (such as TRIFLUORO ACETIC ACID) that manage to pass through the diaphragm. It is also available with a "Backup Diaphragm" to further increase the protection provided. ・ VENTIDUCT protects the fluid from heat...

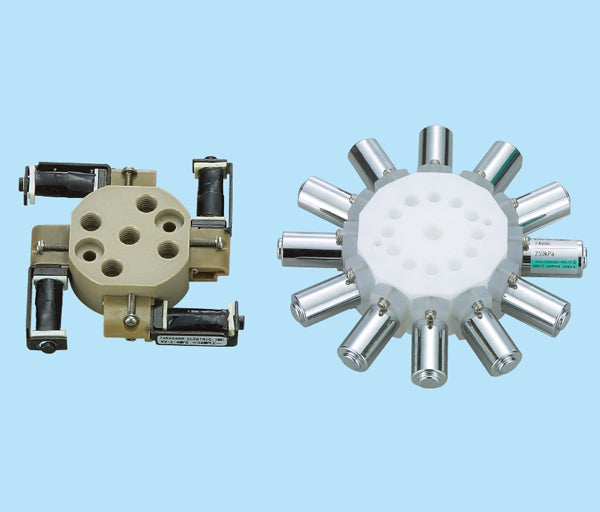

Manifolds

Posted by YamamotoKumiko on

KV-2-4MFG-4 / EXV-2-12MDG If you would like to install diaphragm valves compactly and connect flow paths over a short distance, the manifold is the best choice. If you let us know the flow pattern you require, we can design and produce the product to meet your requirements. A variety of shapes, materials, and structural methods are available, and we are also capable of equipping the manifold with components like diaphragm valves, pumps, etc. Note: Details such as specifications, etc., may be changed without notice. List of Takasago's Manifolds For more information or details, please feel free to contact us...

Latching Solenoid Valve

Posted by YamamotoKumiko on

Reduce environmental impact! Promote green tech with energy-saving valves! What is the "Latching Solenoid Valve"? In a conventional normally closed solenoid valve, continuous power is required to maintain the valve in an open state. In contrast, a latching solenoid valve utilizes a permanent magnet to hold the valve open without the need for continuous power. For a more detailed explanation of the latching mechanism, please refer to our technical guide on the Operation Principles of the Latching Mechanism. >> Jump to Product Inquiry Benefits of using the Latching Solenoid Valve Eco-friendly and energy efficient:A latching solenoid valve does not require...

Position-Feed-Back Shaft

Posted by YamamotoKumiko on

The Position-Feed-Back Shaft, projected at the top of the valve, moves up and down correspondence to the valve opening and closing. The shaft can transmit the valve's motion to a microswitch for sending a reliable feedback signal of the on-off status to the control system. Effectively, by feeding back the valve motion itself, the Position-Feed-Back Shaft enhances the reliability by constantly monitoring the valve status compared to traditional methods monitoring an electrical current sent to the valve. We highly recommend this part for reliability-oriented applications. Note: Details such as specifications, etc., may be changed without notice. Applicable Models MTV...