- News & Events

- Space Beer-brewing device! Fermentation experiments under micro gravity!

Space Beer-brewing device! Fermentation experiments under micro gravity!

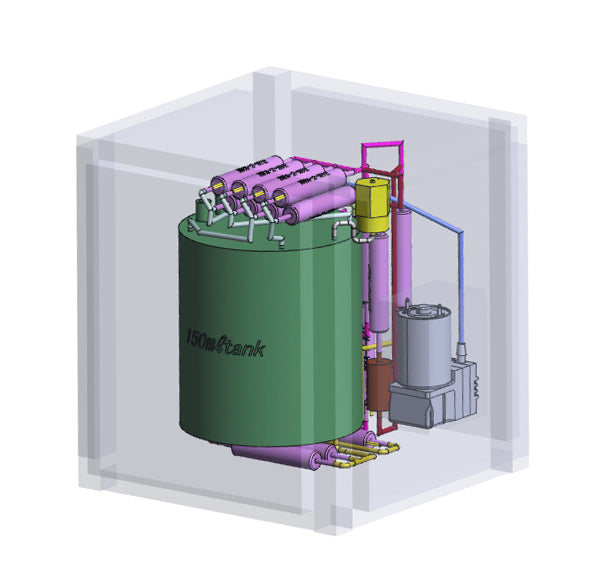

Takasago has designed an automatic device for experimental beer brewing on satellites and space stations. We are planning to exhibit the first prototype at an event held by SPACE FOODSPHERE, an organization that aims to solve food problems of both the earth and space together, which we are a member of. Our goal is to conduct an experiment on a satellite in orbit.

It is said that humanity will live in outer space in the near future. In order to make such a scenario viable it will be imperative to develop technologies that can produce food and beverages with the same quality and flavor as back on Earth, while working with limited resources.

How will the fermentation process change in space, which is very different from the environment on the ground? What fermentation conditions are optimal?

In 2017, Takasago provided parts and technical advice for a lunar beer-brewing device developed by students from UCSD. The moon although weaker than Earth, has gravity. However, in order to produce beer under zero gravity conditions we need a completely closed system and more advanced technology, for processes such as degassing and stirring. This time, we solved such problems and applied for a patent.

Can we make delicious beer in space? It is a scientific quest that tickles intellectual curiosity and excites people. Making a toast while watching the earth with a beer made in space! Don't you think it's exciting? This is a project full of dreams and hopes, looking to the future of humankind aiming for space!

Features

- Joint development with ALE Co., Ltd., which carries out artificial shooting star business operations.

- Fully-automated beer-brewing device to be used in an artificial satellite (under microgravity).

- Suitable for CubeSat class micro satellites. The main body can be stored in 1U.

- Closed-system equipped with a degasser to release CO2 generated during fermentation.

- Multi-direction circulating tank to stir wort even under the micro gravity where heat convection does not occur.

- Hop column for an automatic hopping process in order to add fine bitterness and aroma.

- Applicable to fermentation of wine.

Through participation in the SPACE FOODSPHERE program, we Takasago, as a fluidic solution provider, will implement various fluid control applications such as plant factories, artificially-cultured meet, beer brewing, water treatment, and water quality analysis.

*TFS has resigned from SPACE FOODSPHERE as of the end of March 2024