Aerospace Field

For the space industry, TFS has provided thruster valves for satellite propulsion systems, as well as high-pressure valves, micro pumps, etc. for space experimental devices or spacecraft service modules. Since the foundation in 1959, TFS has built a track-record of high-level quality control, highly customised products and high-mix low-volume production in the medical field. These strengths are now also utilised for our aerospace products. In particular, automated cell culture technology for regenerative medicine characterises TFS as one of a few manufacturers of microgravity cell culture devices in the world.

For aircrafts, we also have developed various valves. In addition, we supply precision machined parts to a Tier 2 supplier for Mitsubishi aircraft and Embraer airframes.

Strengths of Takasago Fluidic Systems

- Advanced quality control and process control based on 40-years’ experience in the medical field

- Specialists in custom engineering and high-mix low-volume production

- Realization of miniaturization and weight saving

- Facilities in the US and China

- Integrated production from design and material machining to assembly and inspection

Valves and Other Fluidic Devices

Aviation

Aviation

-

Solenoid Valves, Check Valves and Pinch Valves

for pneumatic control

for hydraulic systems

for air conditioning and oxygen supply systems

for beverage dispensers and galley equipment

for lavatory equipment

-

Proportional valves

for fuel control experiments

-

Electromagnetic actuators (solenoids)

-

Miniature pumps

Space

Space

-

Thruster Valves

-

High Pressure Control Valves

-

Latching Valves

-

Integrated Fluidic Systems for Space Experiments

-

Automated Cell Culture Systems Used in the Microgravity Environment

Examples of production and adoption

-

-

HVA/HVAL Series Valves

-

HVC Series Valves

-

HVD/HVDL Series Valves

-

UDV Series Valves

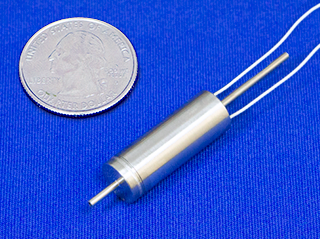

Thruster valves for 2 – 20N class satellite propulsion systems.

-

-

Pilot-Operated Rapid Pressure Control Valves

-

High-Response Proportional Valve for an Experimental Jet Engine